UC Davis Medical Centre

DAVIS, CALIFORNIA

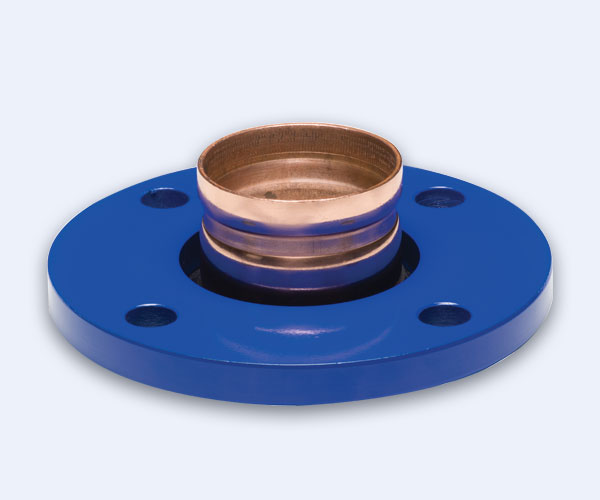

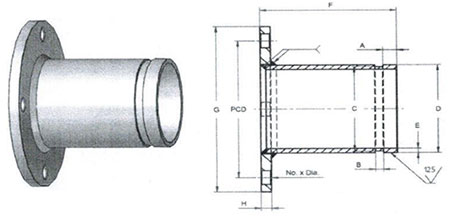

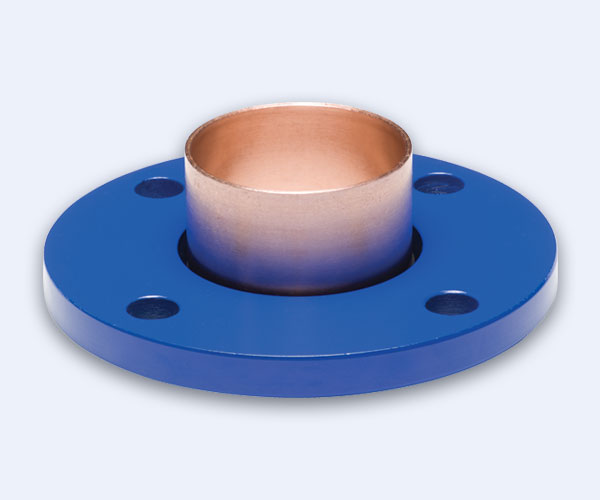

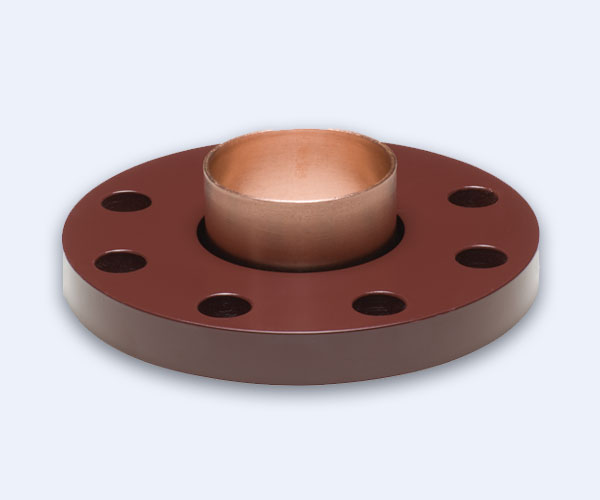

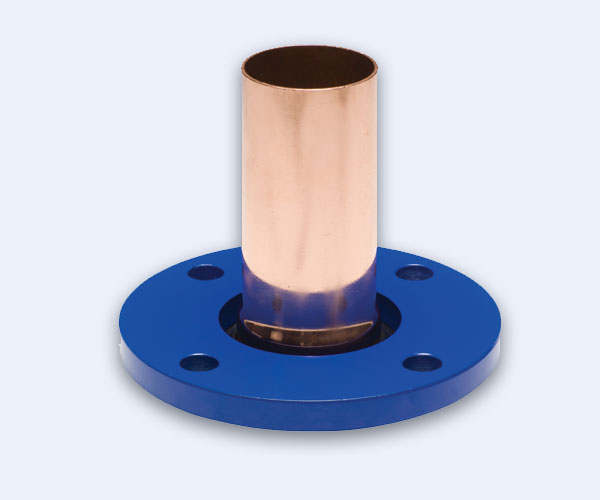

UC Davis Medical Center serves a 65,000-square-mile area that includes 33 counties and 6 million residents across Northern and Central California. The 645-bed acute-care teaching hospital provides vital care to more than 200,000 patients every year. CTS Flanges were used extensively at the Centre saving hours in labor costs.